In December, we summarised what we found out in our first round of workshops researching how plastic packaging gets made. This work will enable us to design a Plastics Packaging Portal (PPP) that will help tackle the UK’s million-tonne plastic-waste problem. This work is backed by Innovate UK.

Since then, we have done more stakeholder-engagement workshops to continue developing and delivering on this plan, which will include:

- a new open standard for plastic-packaging data

- an extension of the the Open3R Household Waste Recycling Centre data standard, which we started developing last year with Your Dsposal to help standardise information about local recycling facilities

- online portals to streamline the collection of these two datasets, enabling them to be linked together and opening up access to this data for everyone along the plastic-packaging value chain

The ‘alpha phase’

The ‘discovery phase’ brought us clarity around how the plastics packaging value-chain is organised, and what the general pain points are that frustrate people.

Participants often mentioned unease with the lack of clarity regarding changes to relevant regulations, as well as a general lack of data transparency and consistency. The combination of these factors seemed to create a sense of mistrust in data and in the current system.

During this first phase, we also started getting a sense of the key data fields that could be included in our new standard.

When moving onto the next stage in the design process, the Government Digital Service Manual suggests that:

“Alpha is a chance to explore new approaches.”

Hence, one of our main aims in the ‘alpha phase’ was to work with our stakeholders to test our assumptions about the data fields, along with the items that would make up ‘controlled lists’ within each field.

We ran six stakeholder workshops with people from across the value chain, including brands, manufacturers, compliance schemes, recyclers, trade bodies and government. In total, we spoke with 38 people and engaged 42 organisations.

Compared to the ‘discovery phase’, our ‘alpha’ approach was much more iterative, meaning that after each workshop, we would update the standard to reflect the outcomes of that discussion.

This proved to be a really effective approach, so that, by the end of alpha, we had considered all of the data fields at length and we felt like we had a good understanding of the value of each one.

Definitions

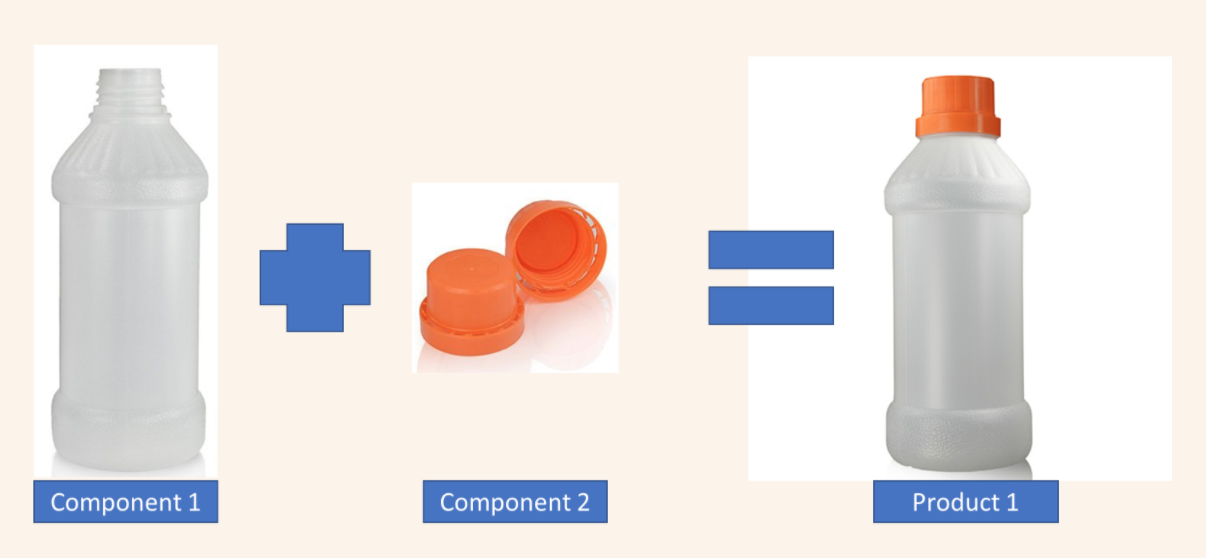

During this phase, we made good progress on definitions and data fields for the standard. We opted to use a granular approach to refer to packaging components. Components can be things like lids, bottles and labels. When combined, they form a product.

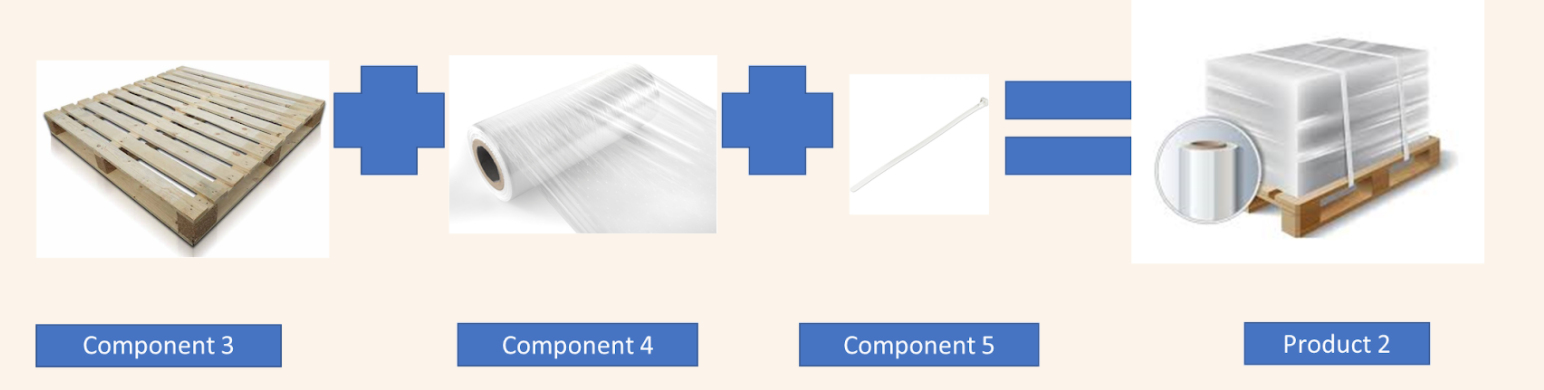

As we found in the workshops where we considered ‘secondary’ and ‘tertiary’ packaging, pallets, shrinkwrap and other components used to transport products are often compiled together and given a single barcode.

Thus, when all of these components are put together, they are treated as another product.

Service design

In addition to the stakeholder-engagement workshops, we also ran a service-design workshop with our fellow consortium organisations – Dsposal, RECOUP and Ecosurety – led by OPRL, which runs the UK’s most widely recognised recycling label scheme for packaging.

We had a good understanding of the broad universe of plastic packaging and now needed to start narrowing down our scope. So we posed the questions:

- “who will be our main users?”

- “what journey do we want to take them through?”

- “what problems will we aim to solve for them?”

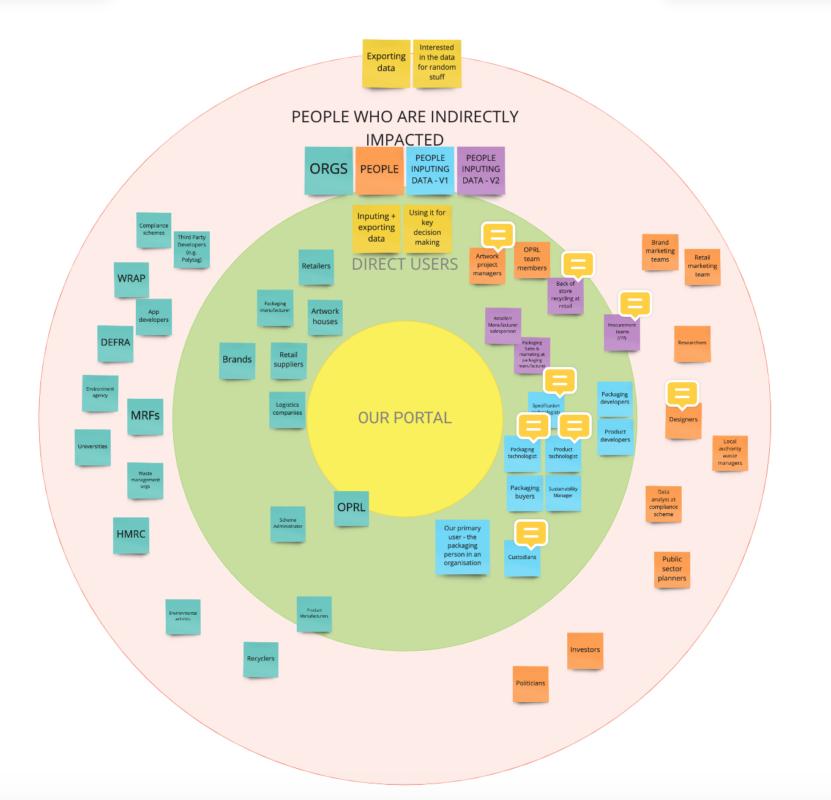

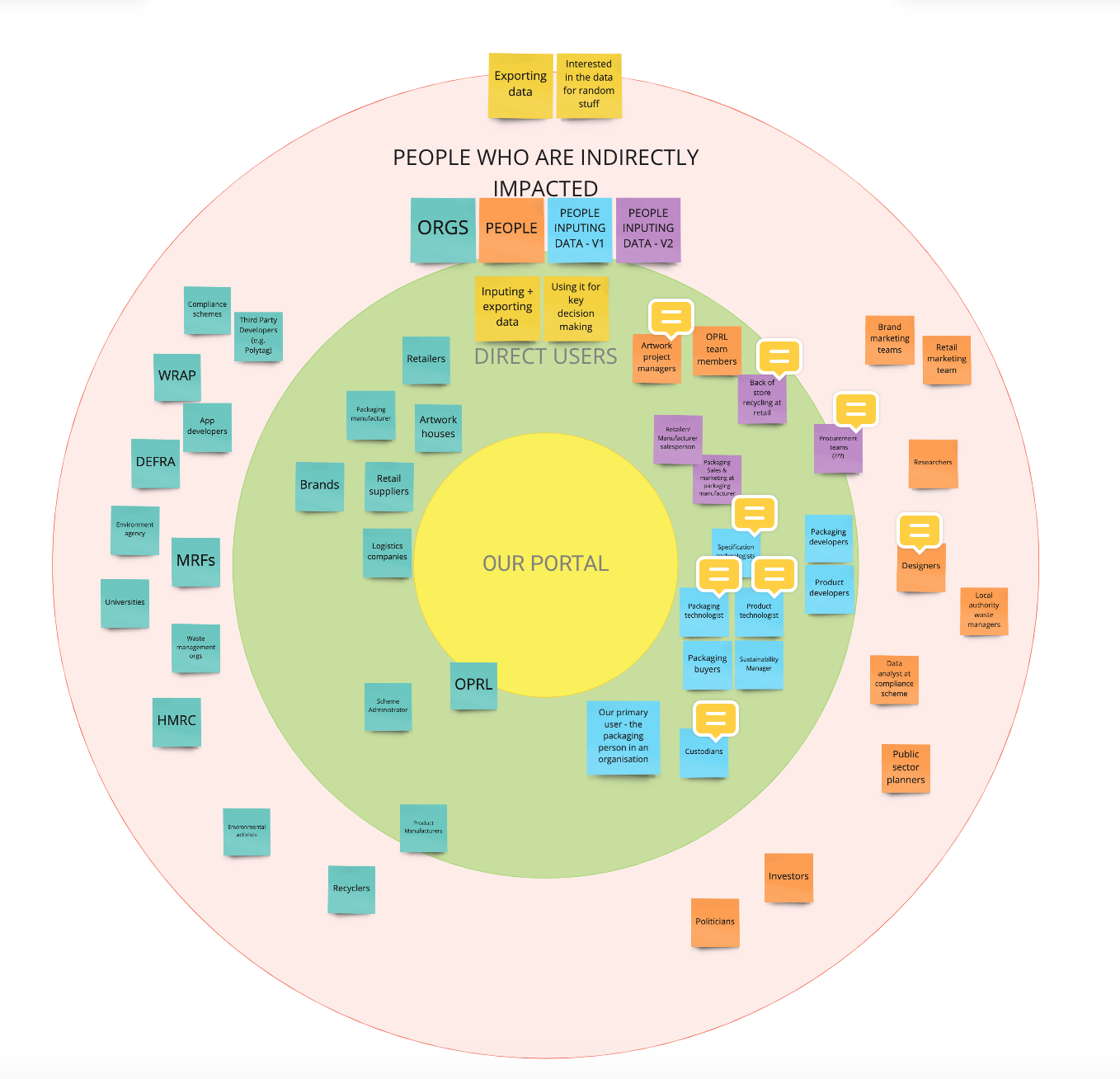

Our starting point was a user-mapping diagram, where we reflected on who would be interacting with our portal directly and who may be indirectly affected by it.

It quickly surfaced that we had a lot of people that could benefit from our service, but that the two main types of organisations that would input and export data, as well as using it for key decision-making, would be packaging manufacturers and product developers.

Personas

Packaging manufacturers

We defined this persona as a container for people with different job titles (e.g. technologists, designers, marketing and sales) but those who ultimately have knowledge about and are responsible for specifications for packaging components produced by their organisations.

We knew what these users could use PPP for, but what we wanted to get really clear on what might motivate them to input data into our system. What could we provide as an incentive for them?

- PPP could be a repository for all of their packaging data, which would help avoid duplication and keep all information needed for reporting and auditing in one place, especially for new initiatives like Extended Producer Responsibility (EPR) and Plastics Tax (a key pain point uncovered in Discovery)

- If they are OPRL members, our system could also have an API that connects with OPRL’s systems, which would allow users to input data once and benefit from getting a recyclability score, which they could use as a selling point for product developers

- PPP could also be the place where product developers select their packaging when creating new products

- In turn, manufacturers could use it to spot trends and gain market insights

With that in mind, it would be important for packaging manufacturers accessing PPP to be able to:

- Create a catalogue of components by:

- Bulk uploading an existing database during onboarding

- Input specifications for new packaging components that they develop

- Edit and update specifications for existing packaging

- Get feedback on packaging recyclability [OPRL members]

- Get visibility of packaging trends

- Export data for reports

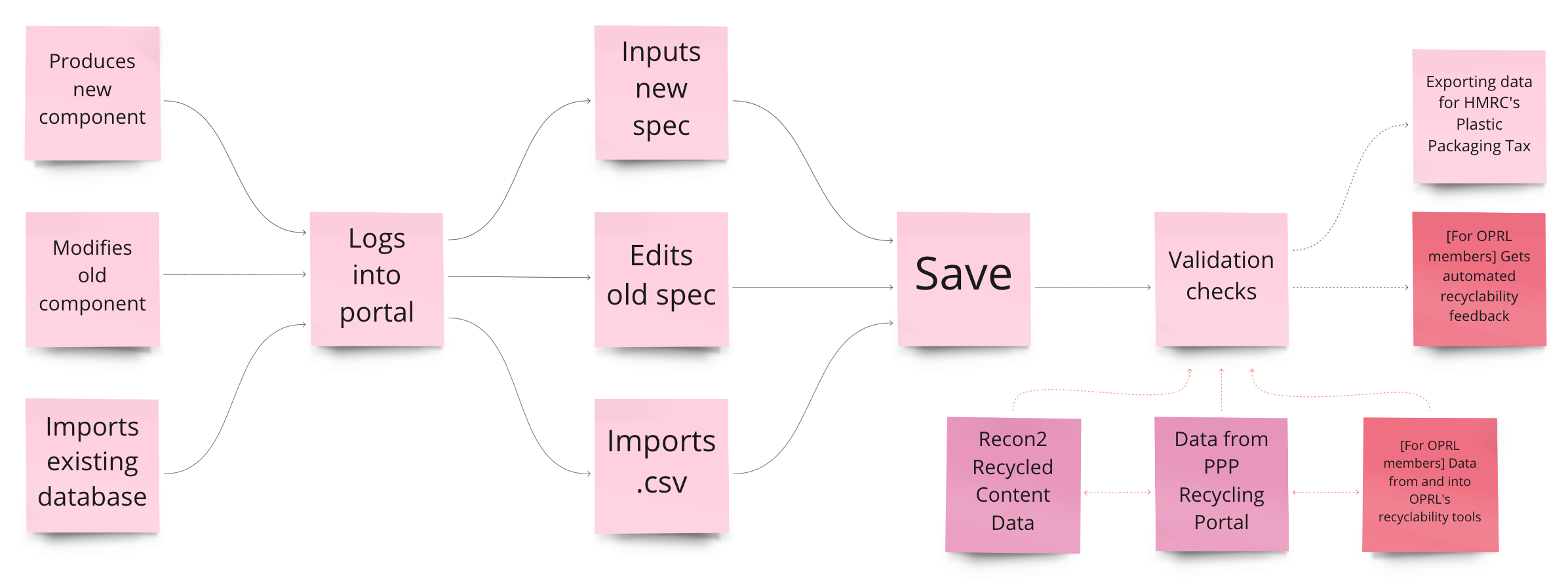

After brainstorming around these motivators and key actions, we drafted the following flow to summarise the journey we’d like to take this user through.

These packaging manufacturers would thus create a catalogue of components that could be viewed and selected by product developers.

Product developers

Our second key persona, product developers, also encompasses different job titles, but would refer to people that have knowledge about and responsibility for selecting and buying packaging for new and existing products. This could include packaging technologists, product designers, marketing and sales people, and specification technicians.

We also wanted to understand what would motivate them to use PPP:

- PPP could be where they research and select packaging components for their products from catalogues, especially if they can see the full specifications for them, such as recycled content and recyclability scores

- Similarly to the previous persona, they could use PPP as a repository for data on the packaging that they currently use, which would help avoid duplication and make gathering data for reporting and auditing easier, such as reporting to the scheme administrator for the new EPR regime

- If they are OPRL members, the aforementioned API could also provide them with a recyclability score based on the product they would be filling the packaging with, as well as a pathway to getting their OPRL label

So it would be essential that this type of user could use PPP to:

- research and select packaging components for new and existing products

- select how much of each component and product would be on the market

- get feedback on packaging recyclability and link to OPRL label [OPRL members]

- export data for reports

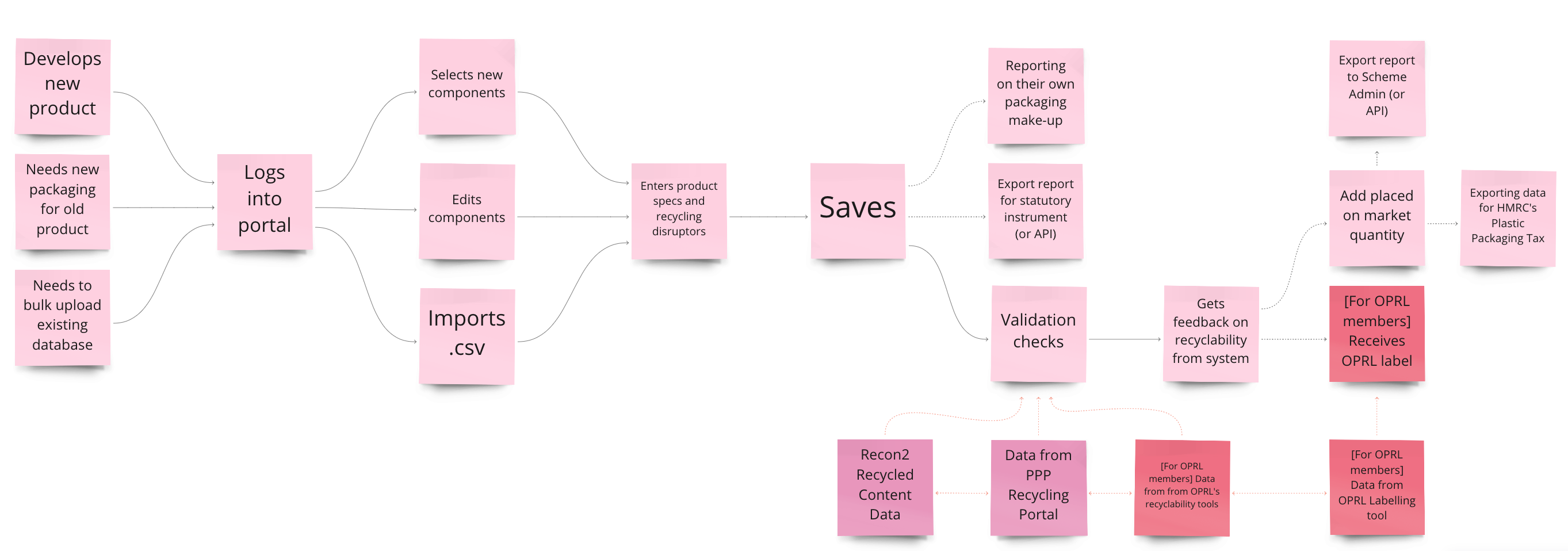

The following flow summarises the journey we would like to take this user through.

So product developers would select packaging components from manufacturers and use it to assemble their product, along with its unique identifier.

What’s next + how you can get involved

We’ve written a full report of this research phase, which you can download here.

We are now moving into our ‘beta phase’, where we aim to:

- validate our personas’ motivators and actions with stakeholders, through one-to-one interviews

- develop and validate our data fields further, especially definitions and controlled lists

- get started with wireframing the design for the portal

This means that we will be hosting a third round of stakeholder workshops in June. They are open to people who have been involved so far, but to new people too, so don’t be shy to book yourself a place.